Turning a passion for flying into a powerhouse of quality and innovation

Beginning in 1990 with little more than a passion for flying and an idea, Helix has quickly grown into a powerhouse of quality and innovation. We currently ship more than 10,000 propellers annually worldwide and service a variety of industries.

Visit us in Friedrichshaven, Germany at the Friedrichshaven Expo Center!

Ramon Morillas achieves new altitude record with Vittorazi’s Cosmos300

We’re excited to be taking part in the 2024 Sun n’ Fun Fly-In in Lakeland, Florida! See you there!

Helix is here to answer the call with performance and the peace of mind that only the best can bring. Reach for the horizon. Helix will get you there.

Years of research combined with state of the art techniques and a love for aviation has made Helix stand out as the “go-to” producer of super strong, light weight propellers and rotors.

These three words can mean almost anything to anyone, but to a paramotorist, they mean everything. As a dedicated partner in the paramotoring world, Helix has long provided the best propellers in a variety of configurations to get you the most out of those three words.

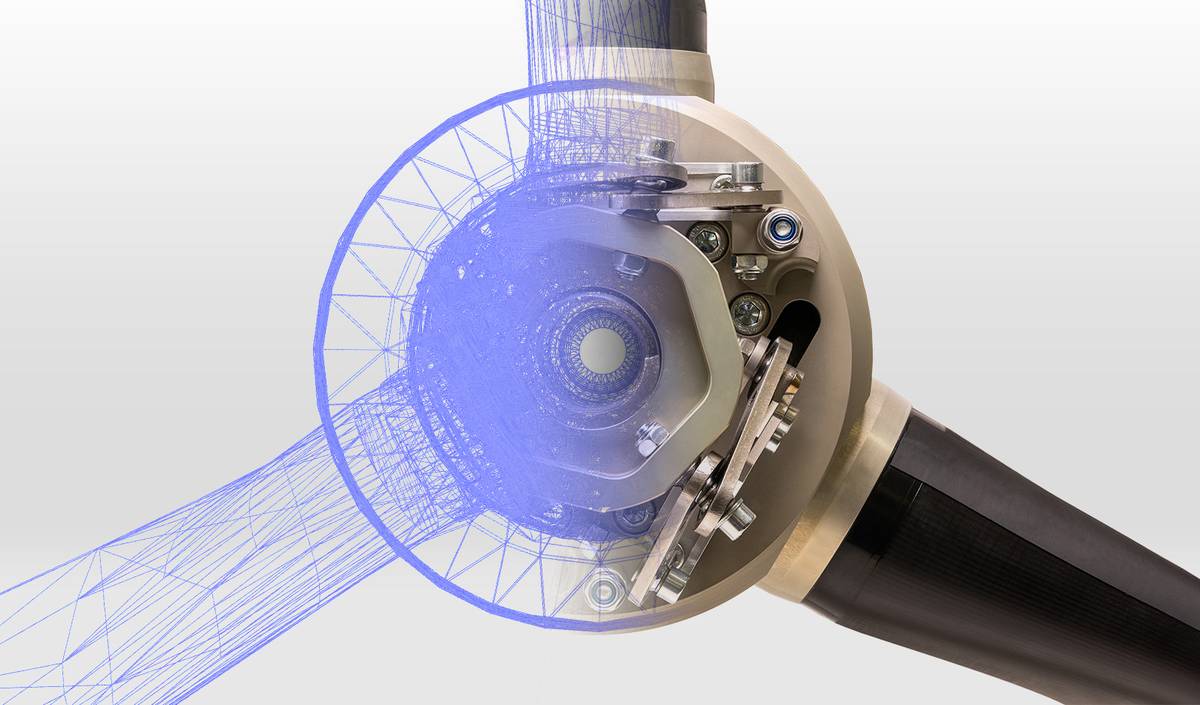

We are proud to maintain a tradition of craftmanship throughout our line of propellers. From beginning to end, our propellers are individually constructed and finished by hand.

Helix is proud to be working together with manufacturers of multicopter and eVTOL vehicles for both civilian and military applications. Our propellers and rotor systems are helping to power the cutting edge of computer-aided flight.

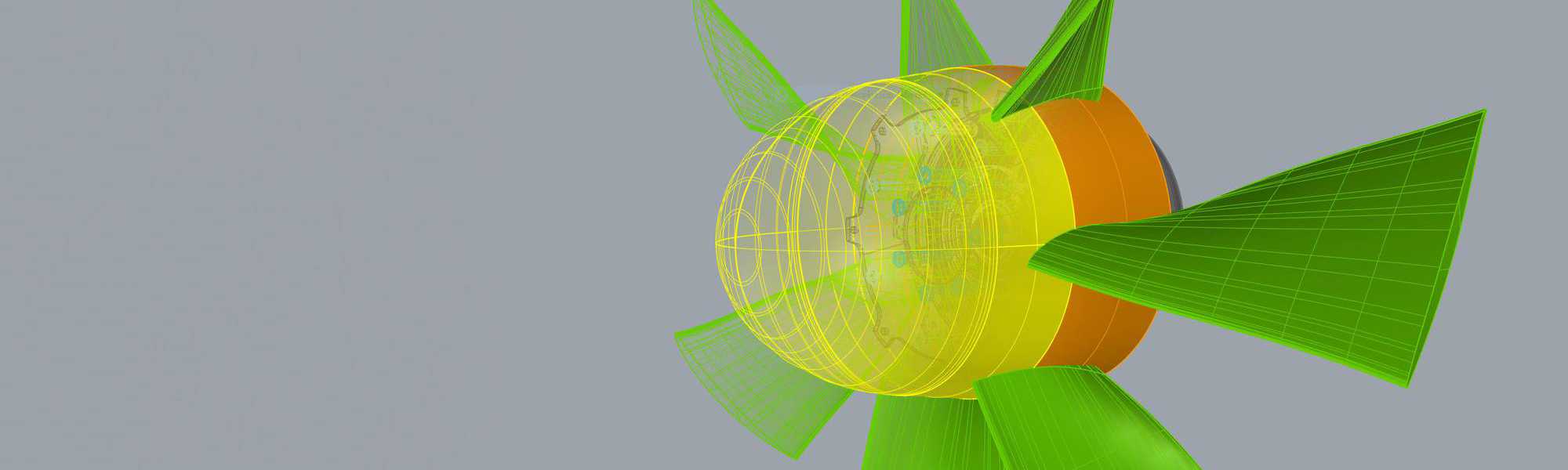

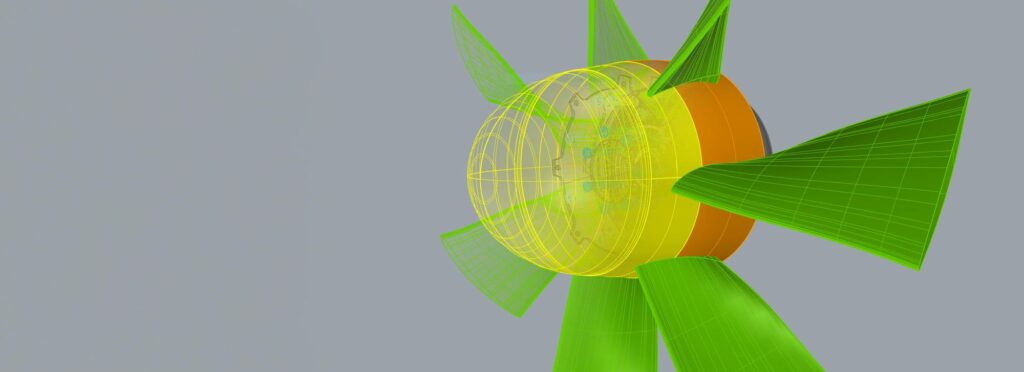

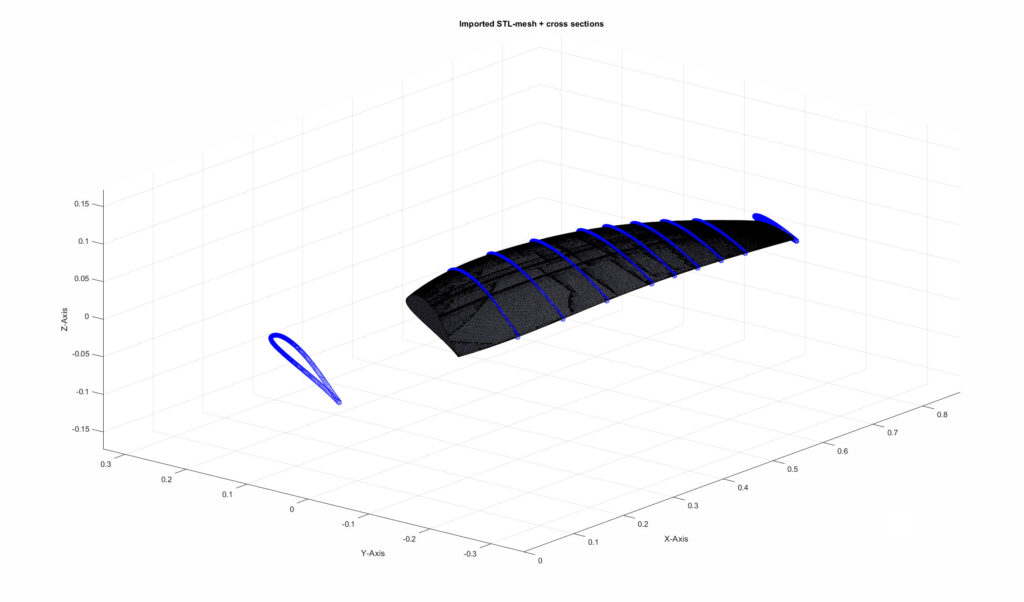

From the virtual drawing board to precision testing equipment: the production timeline of every single Helix propeller is accompanied by cutting edge technology, ensuring the smoothest possible flying experience.

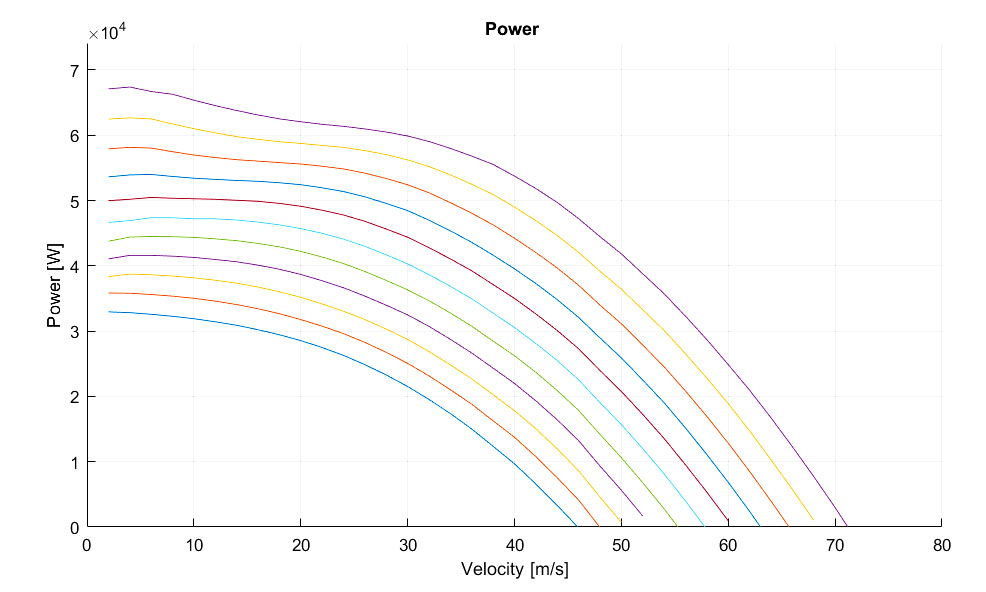

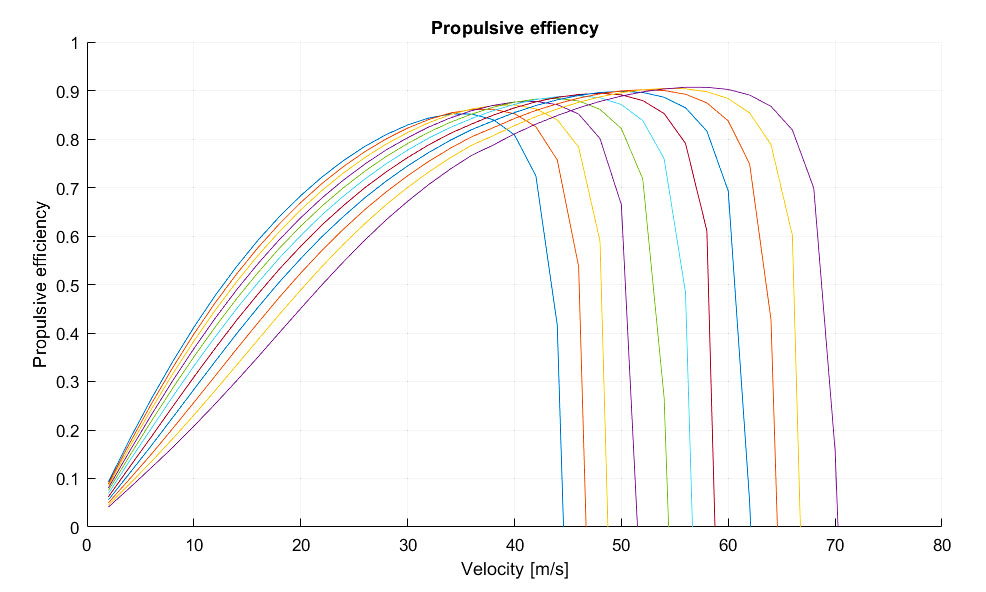

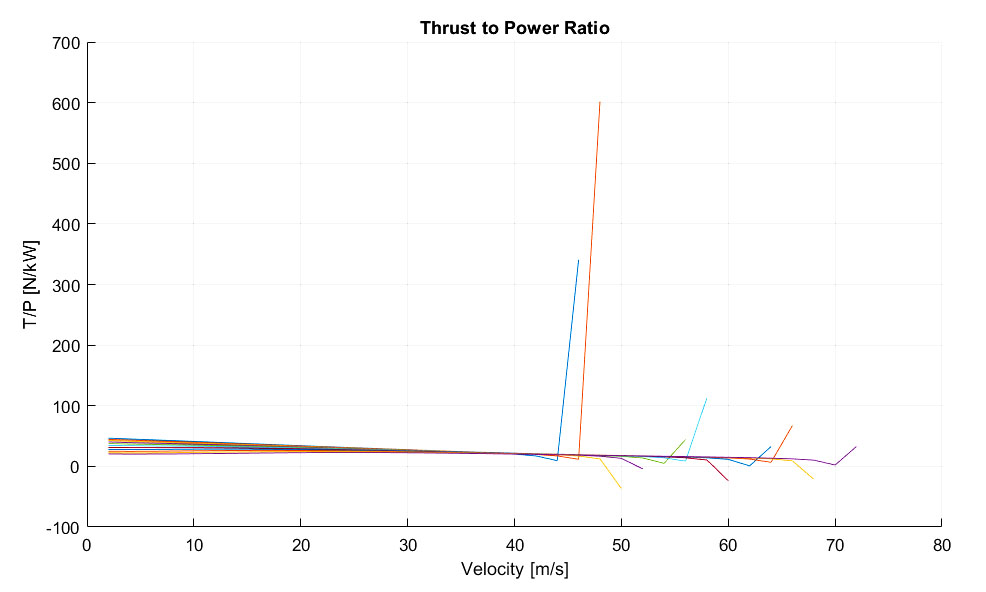

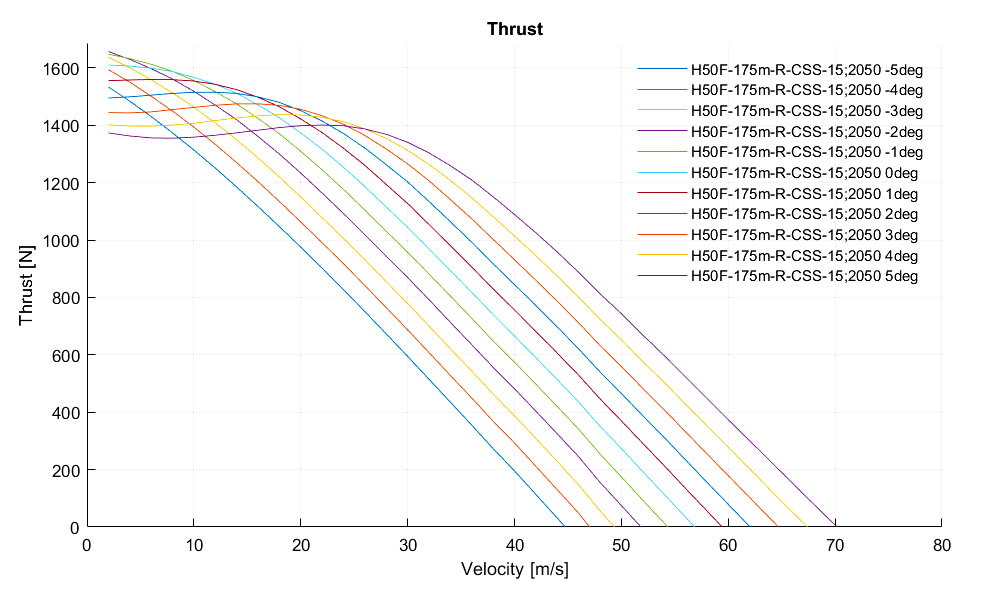

All of our propellers are designed by skilled engineers. With the help of CAD and advanced simulations, we are able to begin testing even before the propeller sees the light of day.

We love numbers almost as much as we love flying. We do everything possible to ensure that each new propeller meets or exceeds every theoretical demand before any production begins.

Ultralight, Gyro, Paramotor- from complete propeller sets to individual nuts and bolts- it’s all here!

*will open a new tab

European Aviation Safety Agency

Part 21G Certification